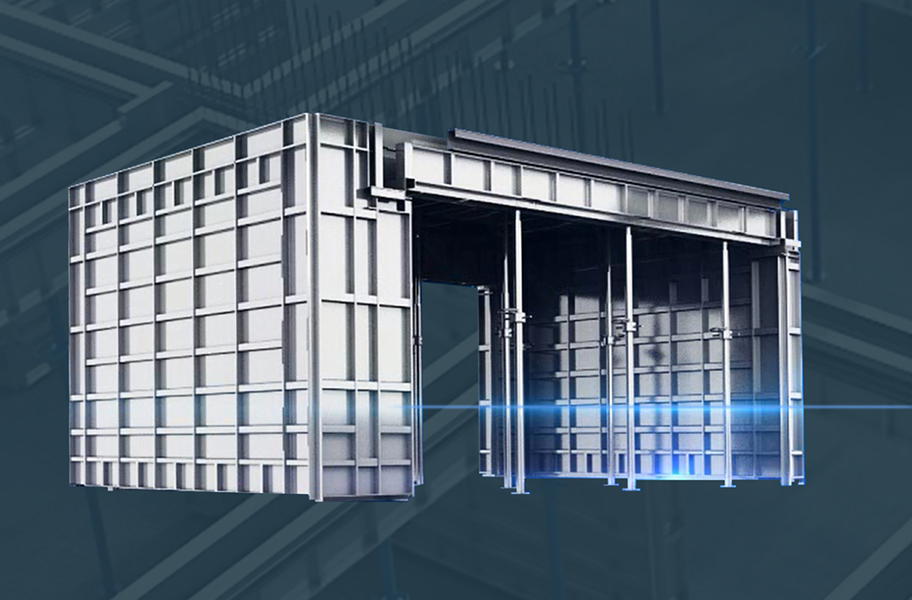

Train Compartment

MACTOLLI

Shandong Mactolli Aluminum formwork Engineering & Technology Co.,Ltd.

Relying on national technology center, national laboratory, perfect aluminium industry production line and aluminium profile machining welding advantages of Conglin Group, Shandong Mactolli Aluminum formwork Engineering & Technology Co.,Ltd. brings R&D, design and installation technologies of South Korea leading alumina formwork, so as to push the new generation of aluminium alloy formwork system via the combined operating mode of sales, lease and construction.

In 2014, Mactolli Aluminum Formwork invested 1 billion to expand 200mu new plant area, annual output of aluminum formwork can be up to 500,000m2.

The company has the management team composed of more than 50 experienced professional design talents, technical experts and industry consultants, more than 500 production and construction specialized team. It is available to provide engineering design, production processing, hosting, refurbishment, recovery, training, construction and other perfect supporting services for various real estate development companies, building companies and leasing companies.

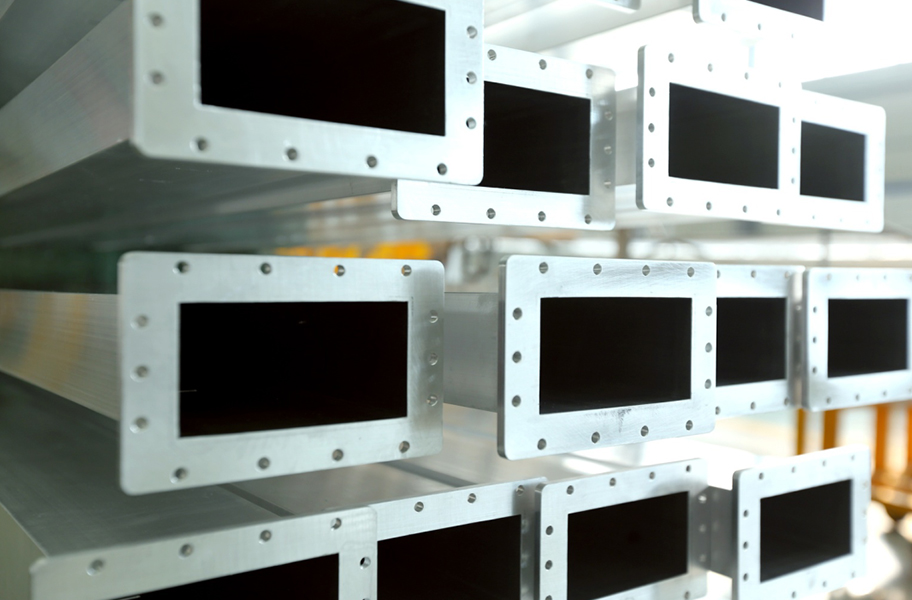

Mactolli Aluminum Formwork has various inspection equipment demanded by EN15085-2 CL1, national aluminium profile and welding testing experiment center, capable of implementing the inspection in the aspects of metallographic phase, chromatography, chemistry and machinery. It is equipped with digital ultrasonic flaw detector, X-ray detectoscope, DHP-06 high-purity argon gas analyzer, DY-L dew point analyzer for process monitoring control to the welding line and welding gas. And now, Mactolli Aluminum Formwork owns international welding engineer, technician, senior welding QA specialist, welding PT detection specialist to constitute the complete welding management system. Mactolli Aluminum Formwork has various inspection equipment demanded by EN15085-2 CL1, national aluminium profile and welding testing experiment center, capable of implementing the inspection in the aspects of metallographic phase, chromatography, chemistry and machinery. It is equipped with digital ultrasonic flaw detector, X-ray detectoscope, DHP-06 high-purity argon gas analyzer, DY-L dew point analyzer for process monitoring control to the welding line and welding gas. And now, Mactolli Aluminum Formwork owns international welding engineer, technician, senior welding QA specialist, welding PT detection specialist to constitute the complete welding management system.

Conglin group has the domestic largest first set of million tons extruding machine in the world, 9000T, 8000T, 7000T, 5600T, 4400T, 3600T, 2000T and other models of extruding machine, it is the domestic largest production base for industrial aluminium profile, which provides high-quality material protection for the good development of Mactolli Aluminum Formwork.

Workshops

Cases

Conglin Aluminum Technology

Conglin Aluminum will devote itself to the R&D and manufacturing of aluminum alloy deep processing and lightweight equipment, continuously expand the application fields of aluminum, and provide high-quality products for rail transit, energy-saving vehicles, offshore equipment, and green buildings.

Copyright © Conglin Aluminum All rights reserved. 鲁ICP备14011465号 Powered by: 300.cn